RAM® Cable Manager for Large Electronic Mounts

Ball Base Information

"RAM" Prefix Code

To provide lightweight strength and corrosion resistance, RAM is made of marine grade Aluminium with a black powder coated finish, stainless steel hardware and 'rubber balls' - 'RAM' products are stiffer and stronger than their 'RAP' variants and typically used in more rugged applications.

"RAP" Prefix Code

Many of our 'RAM' products are available in a 'RAP' - composite variant. Our composite 'RAP' products are generally designed for lighter duty applications where keeping the weight of the mount low is a priority.

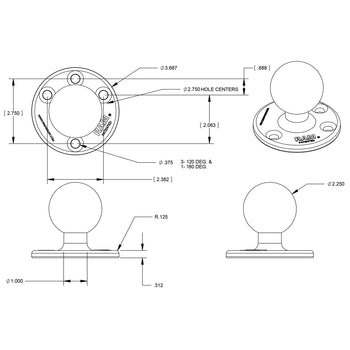

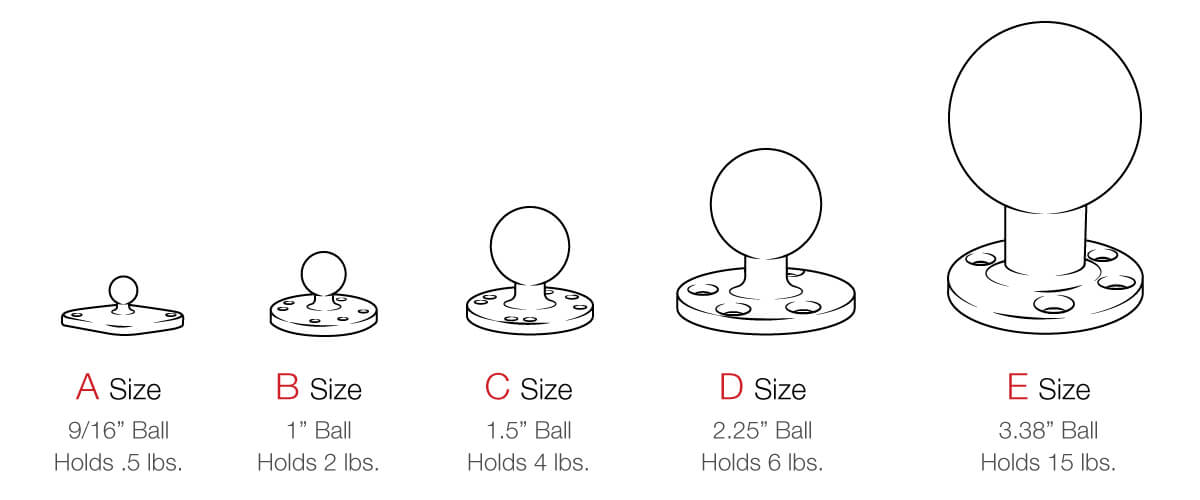

RAM® BALL SIZES

The weight limits below are a guide only. All factors in a planned mounting configuration should be considered to choose the most suitable ball size.

The most common ball size applications:

B Size - Action Cameras, Phones and Small Tablets

C Size - Medium - Large Tablets in Heavier Duty Applications

D Size - Heavy and Rugged Tablets and Laptops in Commercial Applications

Please check with our technical team for advice.

Swipe to see more images.

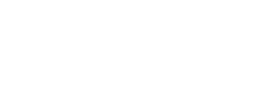

The RAM Cable Manager creates an integrated route for electrical wiring and cleanly covers installation holes. A great addition to any surface mounting application. The RAM Cable Manager is made of glass filled nylon which has the benefit of creating a barrier between the RAM Surface Mount and the attachment area; minimizing vibration while reducing fiberglass and gel-coat damage. This item will fit any of the 3.68" diameter round plates with a 3 hole pattern. (Will not work with the AMPs hole pattern plates)

hardware included

(3) 5/16"-18 x 3" Machine Screws

(3) 5/16"-18 Nylock Nuts

(3) 5/16" Stainless Steel Washers

product dimensions

Cable Slot Height: .45"

Cable Slot Width: .95"

clamp range

Max mounting surface thickness: 1.47"

hole pattern

3-Hole 12-Degree: 2.75" Diameter

materials

High strength composite

packaging type

Poly Bag

Weight

0.227 kg